Debus annealing + heat treatment

When it comes to annealing, quality is not down to chance. It’s down to Debus. In Kreuztal-Buschhütten, our team has been achieving improvement of the properties of metals and steel for 25 years.

The best possible quality and service life is achieved for your work pieces through heat treatment at temperatures of up to 1,050 °C. We guarantee the highest standards for national and international customers thanks to fully digitalised documentation and state-of-the-art furnaces.

Our service portfolio

There are many annealing processes and methods of heat treatment. Choosing precisely the right one requires a great deal of specialist knowledge concerning the combination of heating and cooling processes as well as state-of-the-art furnaces. At the same time, materials such as steels, metals, non-ferrous metals like aluminium 5000 series or 7000 series (T6) require specific know-how in and of themselves. We can offer you both and make our quality promise to you in the process: every work piece that leaves our halls reaches you perfectly prepared for further processing.

Tempering numbers among the low-temperature processes and is used if the material is still too brittle. Optimal adjustment of the ratio of ductility to strength (hardness) is achieved through the tempering process and the work piece's resistance to wear is increased. The two most important parameters for tempering at the tempering temperature and the tempering duration – these vary depending on the material and objective.

Annealing (spheroidising) is used when steels have a carbon content of > 0.8% (hypereutectoid steels). The process here is similar to that of soft annealing, but with the goal of achieving spheroidised carbides instead of a spheroidised, pearlitic basic structure. This annealing process is also used to optimise the properties in order to facilitate subsequent processing steps and achieve a high-quality result.

In contrast to most annealing processes which are used to achieve refinement of the grain in the structure, coarse grain annealing is used to achieve intentional coarsening. The main aim is improved ductibility for further processing steps. The process is carried out at temperatures of between 650 °C – 1,100 °C, with a special emphasis on a sufficient cooling period: in order to keep the stresses in the material low, the long, slow cooling is initially done in the furnace. The work piece is then subsequently air cooled.

We use the homogenisation process in order to eliminate differences in the composition and chemical concentration of alloy elements which occur during casting, forging or rolling. Differences in concentration can cause differences in hardness and internal stresses in the work piece. Through homogenisation at temperatures well below the melting point – at 480 °C to 520 °C for aluminium – the alloy elements are distributed better through the steel, meaning that material variances are reduced and can be machined more easily.

Components which are subject to high strain in particular, such as chassis, car body and engine parts, are made from aluminium alloys today. It is all the more important for the material to maintain its necessary strength thanks to sufficiently precise heat treatment. Solution annealing is used for all heat treatable alloys which can be precipitated and removes the carbide precipitations in the microstructure, thus achieving the elimination of strain hardening. The subsequent extremely rapid air cooling prevents the formation of new strain hardening. The existence of the structure of the treated microstructure even at room temperature and its long-lasting quality is thus achieved and guaranteed.

Normalising has the aim of increasing the ductibility of the steel for low-temperature applications, which is often lost through the preceding cold forming, hot working or welding. Coarse-grained and uneven microstructures are converted into new, homogeneous and fine structures through the process of normalising. For this reason, normalising is often referred to as “structural grain refining” since it is often used to reduce the grain size and its spread. After the normalising process, steel has good machinability but is nevertheless still harder than soft annealed steel. The annealing temperatures are between roughly 800 °C – 950 °C with short dwell times and rapid air cooling.

During the course of production, steels are subjected to multiple forming processes before they reach their final state. In so-called cold forming processes such as pulling, rolling, pressing or compressing, the structure is stretched in the direction of forming and the strength increases, but the formability is reduced. This means an increased risk of crack formation for further forming processes, meaning that multi-stage forming processes in particular are very difficult to carry out. For this reason, the deformed crystals in a structure must be brought back into their initial position before each multi-stage forming process. Recrystallisation annealing is used for this. The aim is to make the steel viscous and coarse-grained again. Recrystallisation annealing is carried out at 500 °C to 750 °C and differs from soft annealing owing to shorter dwell times.

Stresses occur within our work piece or component during the course of mechanical strains such as straightening, machining, milling, turning, casting, welding, cold forming or uneven heating of the material. The occurrence of so-called internal stress is normal, but is problematic for further processing: your component becomes susceptible to cracking or undesirable changes in shape can occur. In the worst case, it even results in breakage and thus in component failure.

In our furnaces, with state-of-the-art burner technology, we reduce the internal stress in your work piece with the stress relief annealing process. Significant stress relief is achieved through controlled heating to temperatures of up to 550 – 650 °C and subsequent cooling. In the end, you get a product which is particularly high quality and has excellent machinability for the subsequent processing steps.

- Solution annealing

Solution annealing is done slightly below the melting point of the aluminium alloy – generally in a temperature range of between 460 °C and 560 °C. The rate of diffusion caused by the high temperature releases large elements in the structure which are detrimental to the mechanical properties of the material. - Quenching

Solution annealing is followed by quenching. This process step is required in order to prevent the supersaturated elements released from precipitating and distribute the alloy elements evenly. Your aluminium structure is now single-phase and metastable. - Artificial ageing or natural ageing

After solution annealing and quenching, your cast parts or components are naturally aged for several days at room temperature, artificially aged for several hours at a moderately increased temperature or subjected to both processes one after another, depending on the composition of the alloy, in order to achieve the desired strength properties through demixing processes. The slow precipitation of the supersaturated elements released starts with the beginning of artificial ageing. At the same time, the strength and hardness increase until they have reached their maximum value. The single-phase material has converted to the two-phase supersaturated initial state, which is then referred to as the T6 state.

As the name suggests, soft annealing is used to establish a soft microstructure and good ductibility. The reduction in strength makes further processing steps such as rolling significantly easier. In addition to steels, non-ferrous metals can also be soft annealed.

This special annealing process aims to achieve a specific hardness range in your work piece. Procedurally, ferrite-pearlite annealing is comparable to isothermal annealing. After coarse grain annealing, the cooling is deliberately interrupted and split into multiple stages in order to be able to achieve the formation of a balanced ferrite-pearlite structure.

Ferritisation is soft annealing for cast materials. In cast iron, ferritisation aims to release the free cementite and the cementite present in the pearlite into ferrite and graphite, resulting in a significant reduction in the hardness. Reduction of the hardness is required in turn for improved machinability. A temperature range of 700 °C – 760 °C, 790 °C – 900 °C or even 900 °C – 950 °C is selected, depending on the kind of material. This is followed by slow cooling in the furnace at 250 °C to 300 °C.

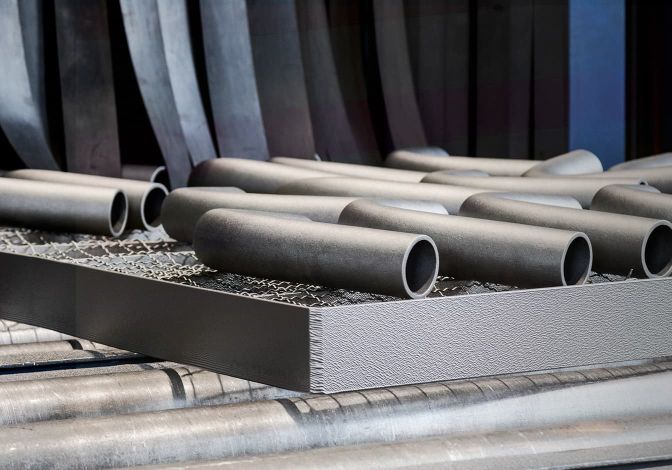

Sandblasting is the pre-treatment which is required for almost all annealing treatments. It is used to remove rust, scale, lacquer and paint residues from steel. Here, the jet of cast iron granulate is applied at high speed using compressed air or shot-blasting wheels. Naturally, sandblasting numbers among our services: our blasting shops offer capacity for work pieces up to 18 metres in length and seven metres wide.

The phoenix story

Getting the best out of your products – that is our stated aim. That's why we also like to talk about the phoenix effect in this context.

25 years of experience

By now, we have been processing work pieces and machine components of all types with the highest standards for industry for 25 years for all sectors.

Extremely precise temperature monitoring

Our digital processes allow for real-time measurements at any point in the annealing process. We thus guarantee you tamper-proof documentation.

Individual test annealing processes

We are happy to facilitate individual test annealing processes until the material meets your requirements and provide you with experience and advice.

Factors for success that speak in favour of DEBUS

Digital production: Our production is completely digital – the heat treatment furnaces can be controlled from the server and the annealing parameters are monitored 24/7. The combination of technology and expertise provides the crucial quality factor.

Pivotal temperature holding levels: Accuracy and precision are our strengths. We satisfy temperature progressions and holding levels which must be precisely adhered to as required.

High-performance team: We know the ropes! By now, we have been applying our extensive knowledge for 25 years and are happy to provide personal advice.

Sustainability: It affects us all. We are investing in sustainable and intelligent solutions step by step in order to neutralise our CO2 emissions.

Industry know-how: We serve a majority of the aluminium industry, power plant and chemical plant construction, the automotive industry, and mechanical and plant engineering, among others. You can rely on quick and smooth processes.

Certifications: We operate a strict quality management system, which is regularly certified in accordance with the standard DIN EN ISO 9001, in order to continually optimise business processes and make operational processes more transparent.